Introduction to Industrial Automation and IoT

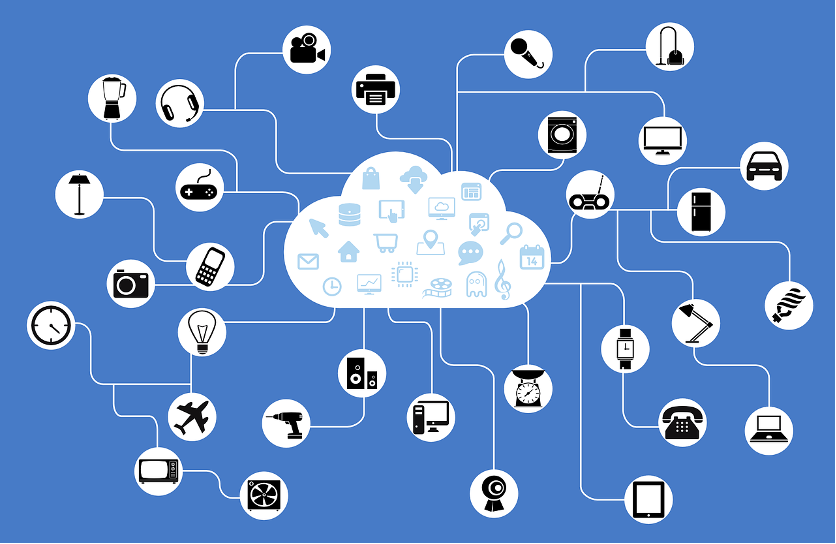

Industrial automation has been a game-changer in various industries, streamlining processes and increasing productivity. However, with the advent of the Internet of Things (IoT), the future of industrial automation is set to reach new heights. IoT, the network of interconnected devices, enables the seamless exchange of data, paving the way for a more efficient and productive industrial landscape.

How IoT is Revolutionizing Industrial Automation

IoT has revolutionized industrial automation by bridging the gap between physical devices and digital systems. By connecting and integrating various devices, sensors, and machines, IoT enables real-time monitoring, control, and optimization of industrial processes. This connectivity empowers businesses to make data-driven decisions, automate routine tasks, and enhance overall operational efficiency.

One key aspect of IoT in industrial automation is the ability to gather and analyze large volumes of data. This data can be used to identify patterns, detect anomalies, and predict maintenance needs, leading to proactive actions that prevent costly downtime. Furthermore, IoT enables remote monitoring and control, allowing operators to access critical information and make necessary adjustments from anywhere in the world.

Benefits of Implementing IoT in Industrial Automation

Implementing IoT in industrial automation brings a multitude of benefits to businesses. Firstly, it enhances operational efficiency by providing real-time visibility into processes, enabling timely interventions and reducing waste. With IoT, businesses can optimize resource allocation, minimize energy consumption, and improve overall production output.

Secondly, IoT-driven industrial automation improves worker safety by automating hazardous tasks and providing real-time alerts in case of any anomalies. This not only reduces the risk of accidents but also ensures a safer working environment for employees.

Additionally, IoT-enabled industrial automation facilitates predictive maintenance, reducing unplanned downtime and extending the lifespan of machinery. By monitoring the performance and health of equipment, businesses can schedule maintenance activities proactively, avoiding costly breakdowns and optimizing maintenance costs.

Case Studies Showcasing the Impact of IoT on Efficiency and Productivity

Several case studies highlight the significant impact of IoT on efficiency and productivity in industrial automation. One such example is the implementation of IoT in a manufacturing plant. By integrating sensors into machines and equipment, the plant achieved real-time monitoring and predictive maintenance. As a result, they experienced a 30% reduction in maintenance costs and a 20% increase in overall equipment effectiveness (OEE).

In another case, a logistics company utilized IoT in their warehouse operations. By deploying IoT sensors to track inventory levels, optimize storage space, and automate order fulfillment, they achieved a 25% reduction in order processing time and a 15% increase in inventory accuracy. This not only improved customer satisfaction but also streamlined their supply chain operations.

These case studies demonstrate the transformative power of IoT in industrial automation, showcasing tangible improvements in efficiency, productivity, and cost savings.

Challenges and Considerations in Integrating IoT with Industrial Automation

While the potential benefits of integrating IoT with industrial automation are vast, several challenges and considerations need to be addressed. Firstly, the sheer volume of data generated by IoT devices can overwhelm existing IT infrastructure. Businesses must invest in robust data storage, processing capabilities, and cybersecurity measures to handle the influx of data securely.

Secondly, interoperability among different IoT devices and systems is crucial. Standardization of protocols and communication interfaces is necessary to ensure seamless integration and data exchange. Without interoperability, businesses may face compatibility issues and disjointed operations.

Furthermore, privacy and security concerns arise with the increased connectivity of industrial systems. Businesses must implement stringent security measures to protect sensitive data and prevent unauthorized access to critical infrastructure.

Best Practices for Implementing IoT in Industrial Automation

To successfully implement IoT in industrial automation, businesses should follow some best practices. Firstly, they should clearly define their objectives and identify the specific processes or areas where IoT can bring the most value. This targeted approach ensures focused implementation and maximizes return on investment.

Secondly, businesses should prioritize scalability and flexibility when designing their IoT infrastructure. As IoT technologies rapidly evolve, the ability to scale up or adapt to new requirements becomes essential. Modular and interoperable systems allow for seamless expansion and integration of new devices and technologies.

Moreover, businesses should prioritize data analytics capabilities to derive actionable insights from the vast amounts of data generated by IoT devices. Advanced analytics tools and machine learning algorithms can uncover hidden patterns, optimize processes, and enable predictive decision-making.

Future Trends and Advancements in IoT and Industrial Automation

The future of industrial automation with IoT holds great promise. As technology continues to advance, several trends and advancements are expected to shape the landscape. Edge computing, for instance, will become more prevalent, allowing data processing and analysis to occur closer to the source, reducing latency and enabling real-time decision-making.

Furthermore, the integration of artificial intelligence (AI) and machine learning (ML) with IoT will unlock new possibilities. AI-powered systems can analyze data in real-time, automate complex processes, and make intelligent recommendations for optimization.

The emergence of 5G networks will also play a significant role in enhancing IoT capabilities. With faster and more reliable connectivity, businesses can achieve near-instantaneous data transfer, enabling seamless communication and control of industrial processes.

The Role of Data Analytics in Optimizing Industrial Automation with IoT

Data analytics plays a crucial role in optimizing industrial automation with IoT. By leveraging advanced analytics techniques, businesses can extract valuable insights from the vast amounts of data generated by IoT devices. These insights can be used to improve operational efficiency, identify bottlenecks, and optimize resource allocation.

Data analytics also enables predictive maintenance, empowering businesses to detect potential equipment failures before they occur. By analyzing historical data and monitoring real-time performance, businesses can schedule maintenance activities proactively and prevent costly breakdowns.

The Future of Industrial Automation with IoT

The future of industrial automation with IoT is promising, with the potential to revolutionize industries across the board. By harnessing the power of IoT, businesses can achieve higher levels of efficiency, productivity, and cost savings. However, successful implementation requires careful planning, addressing challenges, and adhering to best practices. As technology continues to evolve, businesses must stay abreast of the latest trends and advancements to fully capitalize on the transformative potential of IoT in industrial automation.

For more information visit: https://www.it-ai-solutions.com/